What is a Laser Level?

A laser level is an instrument used in construction and woodworking to produce a straight line or reference point from one end to another. It works by emitting light through a laser diode that produces a thin, bright beam of light, usually red or green. This beam can be projected horizontally or vertically depending on the type of laser level being used.

How does a Laser Level work?

At the core of the laser level is a semiconductor called a laser diode that converts energy into light. The laser diode in most laser levels emits infrared light, which the naked eye cannot see. The infrared light is converted into a visible beam using a prism or lens.The laser level's projection mechanism includes a rotating prism or motorized mirrors that reflect the light beam continuously around a room or workspace. The laser level usually has a metal or plastic housing that protects the internal components and allows for easy movement and adjustment.

What are the different types of Laser Levels?

According to specific application scenarios

There are four main types of laser levels: dot lasers, rotary lasers, line lasers, and cross-line lasers.

Dot Lasers: These lasers emit one or more laser dots of light, which serve as a reference point. They are best suited for construction projects that require squaring up layout walls and transferring/aligning plumb points.

Rotary Lasers: It spins a beam lightning-fast enough to give the optical illusion of a solid 360-degree plane. These planes can be horizontal or vertical. A rotary laser level is used for measuring levels and elevations in various construction projects, such as laying out foundations, walls, columns, and more.

Line Lasers: These lasers project a line of light across a surface. They are useful for leveling floors, installing tiles, and ensuring walls are straight.

Cross-Line Lasers: These lasers project both horizontal and vertical lines. They are excellent for indoor applications such as tiling, installing wallpaper, or finishing basements.

Classification according to laser beam color (Red & Green)

Red beam laser levels and green beam laser levels are two types of laser levels that differ in the color of the laser beam they emit.

Red beam laser levels are the most common type and emit a red laser beam easily visible indoors. They are typically less expensive than green beam laser levels and are suitable for most indoor applications.

On the other hand, green beam laser levels emit a green laser beam that is more visible than a red beam, particularly in bright outdoor conditions. This is because the human eye is more sensitive to green than red light. Green beam laser levels are also more accurate than red beam laser levels, making them ideal for outdoor construction and landscaping projects.

However, green beam laser levels are generally more expensive than red beam and may require more battery power. Additionally, they can be more difficult to see indoors due to the presence of ambient light.

Ultimately, the choice between a red beam and green beam laser level depends on the specific application and lighting conditions in which the laser level will be used.

What are the applications of Laser Levels?

Laser levels are used in various applications, including construction, woodworking, surveying, and engineering. They are commonly used for:

Leveling floors and foundations

Installing tiles or carpet

Hanging shelves, cabinets, or pictures

Aligning fence posts

Grading land

Checking elevations

Measuring angles.

What are the advantages and disadvantages of using Laser Levels?

Advantages

High accuracy: Laser levels produce highly accurate results, ensuring that projects are completed with precision.

Time-saving: Laser levels save time and effort by providing a straight line or reference point faster than other traditional methods.

Versatile: Laser levels can be used in a wide range of applications, making them more versatile than traditional tools.

Disadvantages

Cost: Laser levels can be expensive compared to other traditional leveling options.

Battery-powered: Most laser levels are battery-powered, requiring regular charging or replacement of batteries.

Fragile: Laser diodes and prisms in laser levels can be easily damaged if dropped or bumped.

In conclusion, laser levels offer a high degree of precision, speed, and versatility in a variety of applications, from construction to woodworking. Laser levels come in different types suitable for specific applications, and users must understand their advantages and disadvantages before settling on one.

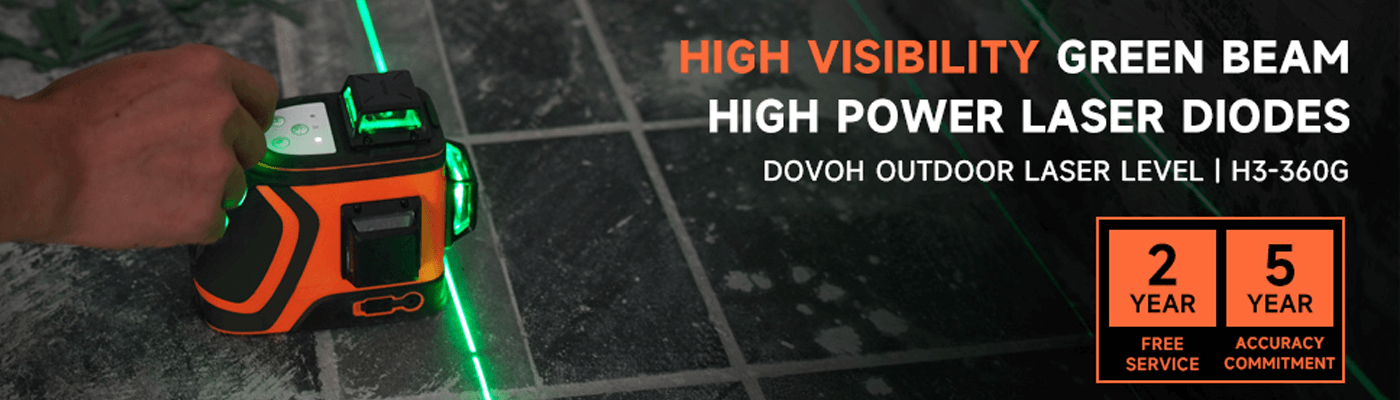

What about Dovoh Laser levels?

Dovoh has been operating in the laser-level industry for over 9 years, offering both cross-line and line laser levels. We have made product improvements aimed at addressing some of the technical challenges in the industry.

One such improvement is the addition of dual high-capacity batteries to address battery life issues. This ensures longer battery life during use, and if the battery runs out of power, the laser level can still be used by plugging it in.

Another key feature of Dovoh laser levels is their reliable accuracy. The sturdy housing with a protective rubber edge helps prevent damage from accidental drops, while the enhanced pendulum framework allows for reliable self-leveling and consistently high accuracy and durability.

Overall, the Dovoh Laser Level Green is a reliable and durable tool that professionals can trust for accurate measurements on the job site. Its sturdy housing and enhanced pendulum framework make it an excellent choice for those who require consistent and precise measurements.

Shop Now: www.dovoh.com

コメントを残す