How to use a laser level for floors?

Accurate flooring installation is crucial for durability, safety, and aesthetics. Precise measurements, proper leveling, and attention to detail ensure a seamless and stable floor surface that enhances the value and appearance of a space.

Using a laser level for flooring installation brings precision and efficiency to the process. It allows for accurate leveling, alignment, and measurement, resulting in a seamless and professional finish. With its ease of use and versatility, a laser level ensures that flooring is installed accurately, saving time and reducing potential errors, leading to a high-quality, visually appealing, and durable floor surface.

This article will explore how to effectively use a laser level for precise and professional floor installation.

I.Understanding Laser Levels

A laser level is an instrument used in construction and woodworking to produce a straight line or reference point from one end to another. It emits light through a laser diode with a thin, bright light beam, usually red or green. Depending on the laser level type, this beam can be projected horizontally or vertically. For the details of the "laser level" introduction, please refer to my previous article, "What is laser level?"

Ⅱ. Calibrate the laser level

Calibrating a laser level is crucial for obtaining precise measurements in construction and other applications. Proper calibration ensures the laser beam is level or plumb, allowing for accurate reference points and measurements. A calibrated laser level eliminates the risk of errors and inconsistencies, which can lead to costly mistakes in construction or other precision-oriented tasks. Calibration also helps maintain the integrity of the laser level's accuracy over time, ensuring reliable results. By taking the time to calibrate a laser level, professionals can achieve precise measurements and improve the quality and safety of their work. About this part, please refer to my previous article How To Check a Laser Level For Accuracy?

Ⅲ. Preparing for Floor Installation

Proper preparation is crucial before using a laser level for flooring. It ensures accurate and precise leveling, avoiding costly mistakes. Properly cleaning the floor, ensuring a stable surface, calibrating the laser level, and setting the appropriate height are vital steps in achieving a flawless flooring installation. Neglecting proper preparation may result in uneven flooring, misalignment, and costly rework.

Ⅳ. Step-by-Step Guide to Using a Laser Level for Flooring

There are two uses for laying floors with a laser level, one is to determine the level height, and the other is to confirm the tile layout.

To use a laser level for floors, you can follow these steps:

First, clean up the construction site and prepare the foundation for laying.

Step 1: Position the laser level in the center of the room on a lifting base.

Step 2: Please turn on the laser level and let it self-level.

Step 3: Mark on the ground or wall at the right height. This will give you a reference point to work from.

Step 4: Use a grade stick or tool to determine if the floor is level. And mark a reference height for each necessary area, and ensure the leveling.

Step 5: Design your tile floor layout using the laser level.

Step 6: Start laying the foundation according to the markings, keeping it level.

Step 7: Prepare to floor laying from that suitable altitude. And use the laser beams to keep the layout of the tiles correct.

Ⅴ. Conclusion

In conclusion, utilizing a laser level for flooring projects is crucial for achieving professional and precise results. From ensuring level floors to accurate measurements for tile or wood installation, a high-accuracy laser level is a valuable tool for flooring professionals. It eliminates human error, minimizes inconsistencies, and saves time and effort in the long run. Flooring experts can ensure accurate layouts, precise cuts, and an excellent finished product by investing in a high-quality laser level and calibrating it before each use. Trusting a laser level for flooring projects is a wise decision that can elevate the quality of workmanship and deliver outstanding results.

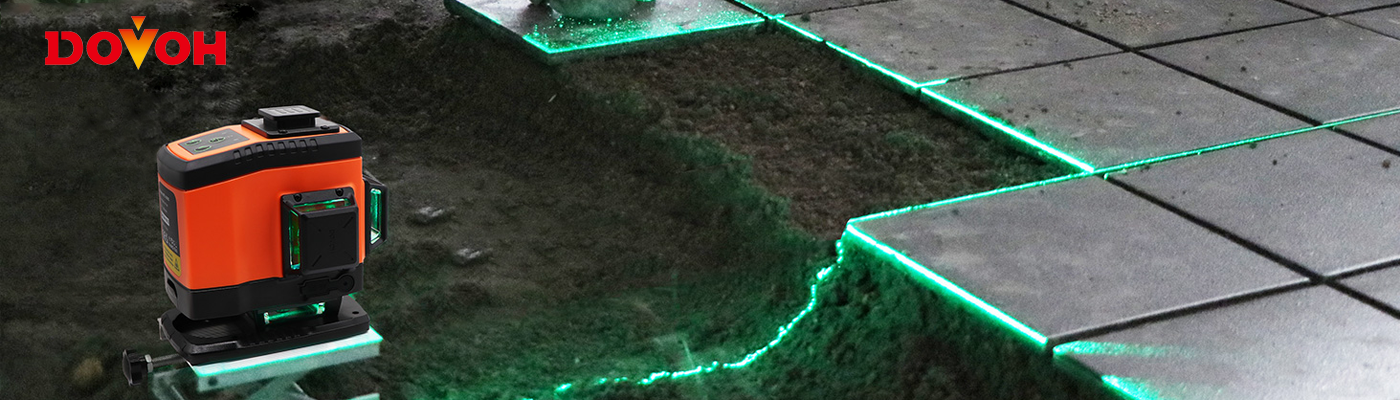

Dovoh Floor laser level recommendation:

https://dovoh.com/collections/floor-laser-level

About Dovoh

DOVOH was established in 2014. We're a leading China-based laser level company with a strong reputation for providing high-quality and precise laser levels for over 10+ years. Our laser levels are sold to China, the United States, the United Kingdom, Germany, Italy, Hungary, Japan, and other countries.

Dovoh professional laser levels' leveling accuracy is ±2mm/ 10m(±1/13 inch at 33ft). It's a good performance in this industry. We use a high-precision axicon component to reflect the high accuracy of the leveling laser beam. The laser level features durable housing surrounded by a rubber edge, and the laser cover is constructed from aluminum alloy. We use top-quality material to make sure it keeps consistently high accuracy.

At DOVOH, we prioritize quality and customer satisfaction. We provide a comprehensive warranty of two years for quality and five years for accuracy for our laser levels, giving our customers peace of mind and confidence in their purchase.

Welcome you to experience the precision and reliability of DOVOH laser levels.

Shop Now: www.dovoh.com

THE RELATED ARTICLE RECOMMENDS:

How to Start Flooring on an Interior Wall

Laisser un commentaire